Occupational health and safety

Key indicators

LTIFR

0,15

Occupational health and safety costs

2,26

KZT billion

KEGOC took the first place among the portfolio companies of Samruk-Kazyna JSC for achievements in the field of industrial safety at the end of 2023

KEGOC implemented the eKAR information system to automate routine business processes in the HSE sector

Key documents

- Development Plan 2023-2032

- Sustainability Management System Guidelines

- Occupational Health and Safety Policy

- Quality, environmental, occupational health and safety objectives

- Hazard and Risk Register

- Occupational Health and Safety Management System Manual

- Occupational Health and Safety Management System Planning Management Standard

- Behavioural Audit Standard

- Standard on safety management in contractors’ work activities

- Regulations on Investigation of Accidents, Incidents and Reporting of Occupational Health and Safety Issues

- Occupational Health and Safety Regulations for Work at Height

Sustainable Development Goals

Management system

Board of Directors

determines the Company’s business lines, approves Development Strategies, sets goals and objectives, and indicators of their achievement

Strategy, Corporate and Sustainability Committee

elaborates on issues in detail and provides recommendations to the BOD

Management Board

ensures the realisation of the goals and objectives set by the BOD

Coordinating Council for Sustainable Development and IMS

makes recommendations to the Board on improving SD and IMS

Ensuring the safety and health of employees is an unconditional priority for the Company. Continuous efforts are made to create safe working conditions, reduce injuries during technological operations, improve the working and sanitary conditions for employees, and minimize the impact of harmful and adverse factors.

The Company operates a Health and Safety Management System that applies to all structural divisions, subsidiaries, and contractors, aiming to ensure effectiveness and improve health and safety performance, and manage risks associated with the Company’s activities. An annual safety and health program is developed, outlining necessary activities, costs, and deadlines. The Company has successfully implemented and certified compliance with the international standard ISO 45001:2018.

2-24, 403-1, 403-8

In accordance with the legislation of the Republic of Kazakhstan, mandatory insurance for employees against workplace accidents is carried out. Additionally, the Company insures employees’ lives and health against non-work-related accidents (24/7) and provides voluntary health insurance to improve social conditions.

Each branch has an Occupational Safety and Health Service responsible for organizational and technical safety measures, internal control over safety compliance, and ensuring employees adhere to safety regulations.

403-3

To facilitate dialogue between employees and the employer on improving safety conditions, KEGOC JSC and its branches have established Occupational Safety and Health Committees with equal representation from the employer and employees. These committees work to ensure safe working conditions and workplace health. Technical inspectors participate in workplace safety inspections. All employees have the right and obligation to stop work if unsafe conditions or actions are identified, and management guarantees full support if employees halt work they consider unsafe.

403-2, 403-3

At least once a quarter, the Occupational Safety and Health Committee reviews employees’ proposals for improving safety conditions and outlines mandatory activities for implementation by the employer and employees.

403-2, 403-4

Risk Assessment

Annual identification and risk assessments are conducted for workplaces. The results are used to create a risk registry and list significant health and safety risks, followed by the development of risk mitigation measures.

Risks are analyzed based on their probability and impact, identifying key risks that could negatively affect KEGOC JSC’s operations and strategic goals. Qualitative or quantitative analysis, or their combination, is used in risk assessment. All KEGOC JSC employees are involved in identifying, assessing, and analyzing hazardous and harmful factors.

Risk assessment and analysis, along with management, are carried out to set goals in occupational safety and health management and achieve an acceptable level of impact on the environment and KEGOC JSC employees.

The results serve as input for developing target and planned indicators. Assessment and analysis are based on activity types and hazard classifiers applicable to KEGOC JSC’s activities, considering geography and climate, and include:

- Hazard and risk identification based on classifiers;

- Risk assessment with existing control measures in place;

- Identification of additional necessary risk management measures;

- Assessment of whether risk management measures are sufficient to reduce risk to an acceptable level.

After identifying impact factors affecting structural division workplaces, a risk registry is completed using the FMEA method. The results form lists of significant occupational safety and health risks for KEGOC JSC. Necessary measures are determined to reduce risk levels and are documented in annual programs.

403-7

One key risk for the Company is workplace accidents.

To minimize this risk, the following activities were conducted in 2023:

- Qualification checks of occupational safety and industrial safety knowledge;

- Analysis of video footage from operational switching and repair work;

- Safety Days;

- Unexpected workplace inspections in MES branches;

- Behavioral safety audits during work;

- Speed compliance monitoring for drivers using satellite systems and reviewing dashcam recordings.

403-2

Employees of the Company undergo all types of mandatory training in safety and health at least once every three years, including qualification checks of knowledge of regulatory acts in the field of energy. In 2023, additional training was conducted on the international standard ‘NEBOSH International General Certificate in Occupational Health and Safety’ and ‘Safety Culture,’ and participation in the ‘KIOSH 2023’ occupational safety and industrial safety conferences.

Before being allowed to work, employees undergo training in safe work methods, on-the-job training, initial qualification checks of knowledge, control exercises, job shadowing, and training under the supervision of a responsible person.

Training on the use of fall protection systems for individual protection against falls from heights was conducted for those authorized to ensure safe work among transmission line personnel.

403-5

Mandatory pre-shift and post-shift medical examinations are conducted for employees engaged in heavy, harmful, or hazardous work, as well as pre-trip and post-trip medical examinations for drivers. Additionally, annual medical examinations are conducted for production personnel to determine their health status, which are carried out by medical institutions in compliance with medical confidentiality, in accordance with the Health Code of the Republic of Kazakhstan.

403-2, 403-3, 403-6

In 2023, no work-related illnesses were registered among KEGOC JSC employees and employees of contracting and outstaffing organizations.

403-10

Injuries

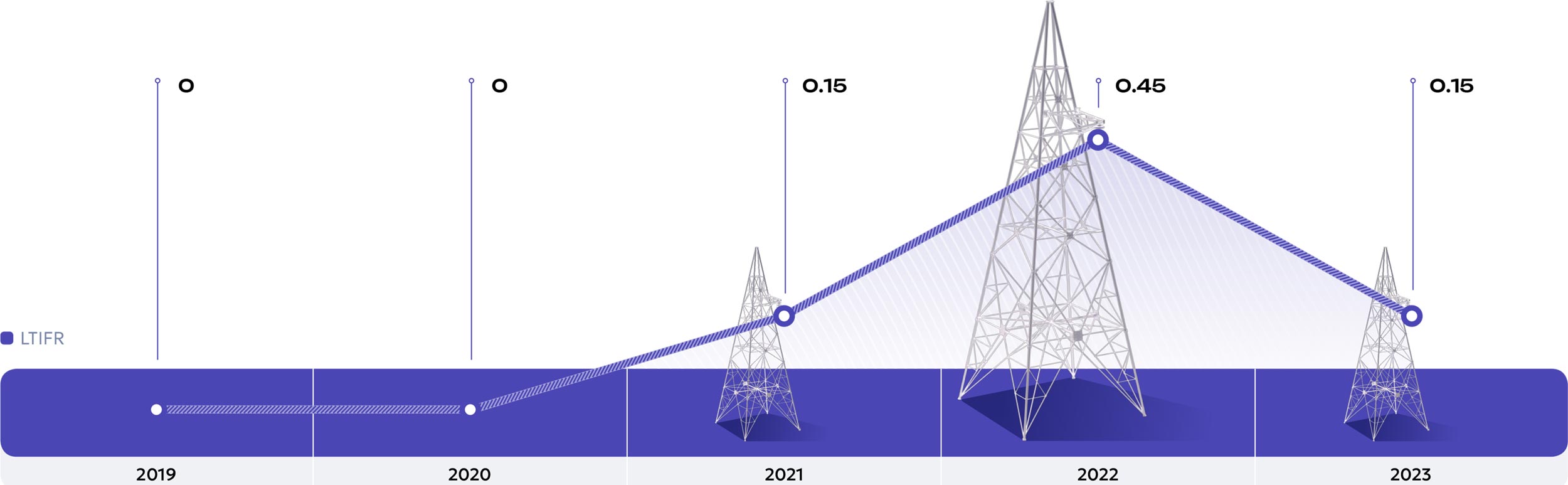

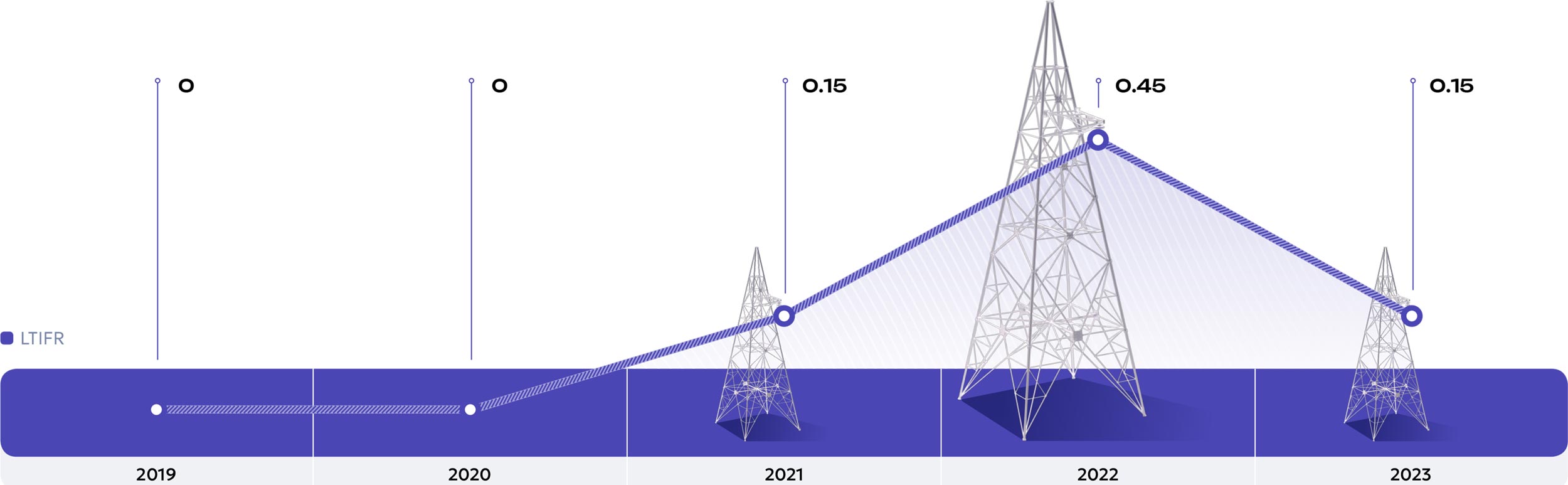

To assess the level of organization of safe working conditions for employees at KEGOC JSC, the LTIFR (Lost Time Injury Frequency Rate) coefficient is used, including fatalities (FAR), related to work activities. In global practice, LTIFR is a key indicator of occupational safety and industrial safety performance. The indicator reflects the number of lost time injuries (LTI) relative to the total hours worked in the Company (Work Hours, WH) normalized to 1 million man-hours. The LTIFR for 2023 was 0.13 (7,578,400 person-hours worked). Without taking into account the data of Energoinform JSC, the lost time injury frequency rate is 0.15 (0.45 in 2022).

403-9

In the event of incidents, Company employees follow rules regulating the processes of incident investigation, incident and safety reporting.

403-2

The causes of work-related accidents inherent to the Company’s activities are:

- falls from heights;

- electric shock;

- road traffic accidents.

403-9

There were no work-related fatalities in 2023.

One work-related accident occurred on October 3, 2023, in the ‘Severnye MES’ branch during work on the 500kV transmission line ‘Ekibastuzskaya-Semey,’ resulting in an employee’s leg injury due to a sudden tension of the pull rope caused by a wire fall due to insulator rupture. After first aid was provided (fixation of the broken leg, application of sterile bandages to the abdominal and leg wounds), the injured employee was taken to the hospital. The special investigation report identified the main causes as equipment design deficiencies, resulting in the destruction of a single suspension insulator in the overhead line suspension hardware installed by a subcontractor.

Corrective measures were developed based on the accident investigation to prevent similar incidents.

Lost time injury frequency rate among KEGOC JSC employees (without taking into account Energoinform JSC)

Work with Contracting Organizations

When work is performed on KEGOC JSC’s facilities by contracting and outstaffing organizations, the Company is responsible for ensuring the safety of their employees. KEGOC JSC’s contracts with contracting and outstaffing organizations include obligations to fully comply with the legislation of the Republic of Kazakhstan and KEGOC JSC’s internal documents on safety and health when performing work and providing services.

Before starting work, introductory meetings are held with representatives of the contracting organizations. Access to work is granted on-site. Prior to accessing the workplace, all employees of the contracting organizations undergo briefings. Specifically, responsible work supervisors conduct briefings on electrical installation schemes. During daily access, targeted briefings are conducted, indicating safety measures, hazardous and harmful production factors present at the Company’s facilities.

KEGOC JSC ensures internal control over the compliance of contracting organizations’ personnel with the legal acts of the Republic of Kazakhstan and KEGOC JSC’s internal documents when performing work and providing services at the Company’s production facilities. The Company also evaluates the contracting organizations’ performance in the field of safety and health. Thus, all employees of contracting and outstaffing organizations (100%) working at the Company’s facilities are covered by KEGOC JSC’s health and safety management system.

In 2023, no accidents and fatalities among employees of contractors and outstaffing organizations related to work activities at our facilities were recorded.

403-5, 403-7, 403-8, 403-9, EU18